Shell & Tube Heat Exchanger, U Tube Bundle, Chlorine Recuperator Heat Exchanger, Coil Type Heat Exchanger, Double Type Heat Exchanger, Double Tube Heat Exchanger, Floating Heat Exchanger, Industrial Heat Exchanger Manufacturer, Lined Heat Exchanger, Cladded Heat Exchanger, Process Heat Exchanger Manufacturers in Mumbai, India.

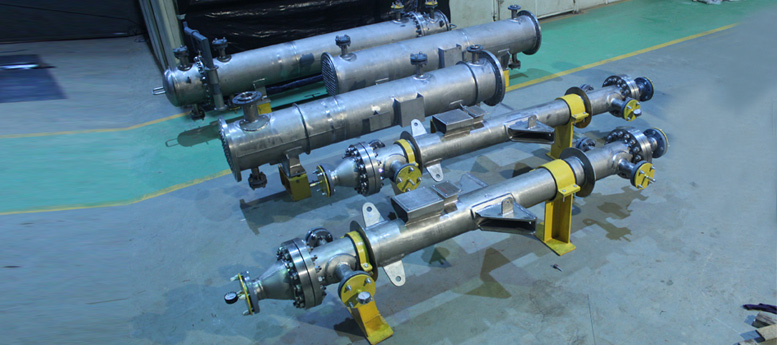

HEAT EXCHANGERS IN EXOTIC METALS

TINITA is one of the Fastest Emerging Brand for STATIC EQUIPMENT in India, Certified by ASME “U” , “R” Stamp Authorities is also ISO 9001:2015, ISO 14001-2015, and ISO 45001-2018 Company & offers EIL & IBR APPROVED product range of PROCESS EQUIPMENT.

Accordion with symbols

In this example we have added a "plus" sign to each button. When the user clicks on the button, the "plus" sign is replaced with a "minus" sign.

Ready Availability: Inventory of exotic materials is maintained at our production units which help us deliver our products ahead of delivery schedule.

Welding : With a highly trained and qualified team of engineers and state-of-art technology at our disposal, we guarantee zero defects in the welding quality of our products.

TINITA delivers EXOTIC GRADE PRODUCTS from complete range of material such as Titanium, Tantalum, Nickel and its alloys, Alloy 904L, Hastelloy 'B' and 'C', Monel, Inconel, Alloy 20, Zirconium, Cupro Nickel, 17-4 PH, Duplex Steel, 2RE-10, and all grades of stainless steel.

Types of Heat Exchanger

In shell & tube Heat exchanger there are series of tubes. One unit has fluids that is either heated or cooled while second unit which runs over the tubes can either give heat or absorb heat to carry the process. In shell-and-tube exchangers, many tubes are mounted inside a shell; one fluid flows in the tubes and the other flows in the shell, outside the tubes.

In double-pipe exchangers, one fluid flows inside the inner pipe, and the other in the space between the two pipes. The design of Heat Exchangers usually includes Tube diameter, Tube thickness, Tube length, Tube pitch and corrugation.

Heat Exchangers are extensively used in Industry for cooling & heating in large scale process and systems. If there is waste of energy which can be recovered it can be used to recover and be used to heat different process without phase change.

Heat Exchanger includes boilers, evaporators, superheaters, condensers, and coolers.

Material of Construction : Titanium, Tantalum, Nickel, Hastelloy, Inconel, Stainless Steel.

Types : Shell & Tube Heat Exchanger, U Tube Bundle, Coil Type, Double Pipe, Floating, Lined, Cladded Heat Exchanger, Process Heat exchanger.

Shell and Tube :The device has series of tubes. One set of tubes contains the fluids that are heated or cooled. The other fluid passes over the tubesthat is heated or cooled so that they give heat or absorb the heat. A set of such tubes is called tube bundle. They are used for high pressure application.

Double Pipe : They have the inner pipes and the outer pipesThe outer pipe is dented forming various projection such as conical shape, cylindrical shape, elliptic etc. It is possible to increase flow of fluid between inner pipe and the outer pipe which results in transfer of heat from fluid flowing in the inner pipe to fluid flowing between the iner pipe and outer pipe.

Floating : It is a device wherein plate block provide cross flow channels between two fluid. It consists of a stack of consecutive rectangular plates

Coil Type : Coil can be used for gas and liquid flows. Coil type exchangers are more efficient as they are almost working like counter flow type exchangers. For the shell side it is optional to use baffles or an inner tube to achieve a special flow pattern.

Cladded : This type of Heat Exchangers is assembled together by suitable joining techniques such as mechanical assemblies.In this method one or more of the components of the heat exchangers such as baffles, end tanks, tubes, fins are attached using brazing . There are various techniques. Most commonly used is Controlled atmosphere brazing. It employs a brazing alloy for attaching components wherein the components are formed of material with higher melting points. The brazing alloy is positioned between components or surface of the components to be joined the brazing alloy is heated and melted.

Industrial Application : Chemical, Petrochemical, Electroplating, Pulp & Paper, Caustic Chlorine, Sea Water, Aerospace, Fertilizer, Dyes & Intermediate, Food Processing, Petroleum Refining, Hydrochloric Acid, Sulphuric Acid, Acetic, Formic, Phosphoric Acid, Chlorination system, Pickling, Sulfonation, Pesticides, Ferric & Cupric Chlorides, Brine solution, wet chlorine, generation of steam for production of electricity, Brine solution, Wet Chlorine gas, Flue gas, Waste water treatment, Refrigeration system, Wine brewery industry.

Exports

Tinita Engineering (P) Ltd. exports with ASME 'U' stamp to SAUDI ARABIA, UAE, KUWAIT, QATAR, OMAN, IRAN, UNITED STATES OF AMERICA, UNITED KINGDOM, AUSTRALIA, SOUTH AFRICA, MEXICO, TURKEY, FRANCE, EUROPEAN UNION, NEW ZEALAND, BAHRAIN, OMAN, YEMEN, LEBANON, SPAIN, INDONESIA, MALASIA, LEBANON, IRAQ, IRAN, EGYPT, MADAGASKAR, SRI LANKA, DENMARK, POLAND, ITALY, BRAZIL, SINGAPORE AND NETHERLANDS.

Enquiry

If you have any Inquiry in regards to this product please contact us on +91-22-50441001 or email us on tinita@tinita.in. Our Experts can guide you on the same and inform in regards to other various metals fit for your applications.